Center pivot irrigation is a crop irrigation technique that involves irrigation equipment which revolves around a pivot. With this type of irrigation, crops within the radius of the pivot point are irrigated in a circular fashion.

Center pivot irrigation equipment is comprised of multiple steel or aluminum pipes. These pipes are connected by trusses to form a rigid framework. The trusses are anchored to the ground by wheeled towers. This overhead mechanism moves in a circular motion above the crops and applies water, supplied by the pivot point in the center, to the crops below through a sprinkler system that spans the length of the pipes.

For more information on center pivot systems and lateral move systems, view the links below.

If you would like more information about our products or services, please contact us today!

Durability, stability, and minimum maintenance - just a few of the qualities that make a Reinke Irrigation System one you can rely on for years to come. Quality workmanship and advanced design are evident throughout the entire pivot structure, and especially in our unique pivot point design.

In 1968, the irrigation industry changed forever. Richard Reinke introduced the Electrogator - the world's first reversible, electric gear driven center pivot system. A classic combination of leading edge engineering, a passion for perfection, and a rich tradition of excellence led to the most innovative irrigation system ever made. More than 30 years later, that first system (Electrogator #1) is still running strong near the company headquarters in Deshler, Nebraska.

The Electrogator was just the beginning of a partnership with growers worldwide that continues to this day - a partnership built on Reinke's dedication to providing growers with durable, reliable, and efficient irrigation systems. Reinke continually searches for ways to extend that partnership with new and enhanced products, including the Alumigator (our all aluminum system), our line of lateral move systems, the patented Energy Saver Package (E.S.P.) with swing arm corner, GPS corner system guidance, and more.

Thirty-five years ago, Reinke created an industry standard, and we're proud to say history has repeated itself with the development of the Electrogator II. Built with the same level of integrity, ingenuity, and attention to detail as the original, the Electrogator II delivers innovative new features that will once again change the way you look at irrigation.

We are committed to enriching our partnership with you, the grower, through our dealer network and through our commitment to quality workmanship and engineering advances. At Reinke, we've made it our mission to exceed your expectations of quality, service, and innovation.

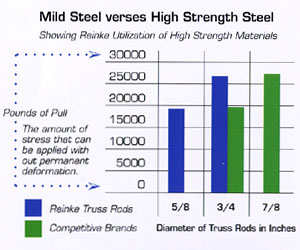

It's simple. You want a durable, trouble-free irrigation system that lasts. With the use of high strength steel and aluminum components, Reinke delivers just that.

Our systems are built with high strength materials to reduce weight and withstand many years of rigorous use in all types of field conditions. This reduces stress on the drive train and reduces the potential for deep wheel tracks, which can damage your field equipment. The result? Your ownership and maintenance costs are significantly reduced and you have a durable irrigation system you can count on for the long run.

Reinke is the only irrigation company that offers you five types of water pipe and several different diameters to accommodate varying water conditions.

If you would like more information about our products or services, please contact us today!

Reinke developed the world's first and only successful aluminum center pivot in 1973. Today, the Alumigator IV is the most prestigious system on the market. Its sixteen-foot wheelbase is the widest in the industry. Total system weight is approximately 40% less than a comparable steel system. The lightweight feature virtually eliminates wheel tracks. The Alumigator IV is the only choice for sod farms and difficult soil types. High strength, corrosion resistant aluminum pipe makes the Reinke Alumigator IV an ideal choice for waste water projects and corrosive water supplies.

If you would like more information about our products or services, please contact us today!

The Reinke Swing Arm Corner System (standard 280' long/370' coverage, including end gun coverage) is available on all new Reinke pivot (non-tow) systems. This exclusive swing span design utilizes a simple ball-and-socket hinge on the last tower. Available in standard height or low profile.

Uniform application of water and chemicals is the result of a computer designed sprinkler package and precision control of the sequential valves.

The Steering sensor is located directly over the wheel for accurate tracking and enclosed in PVC for protection. It is so accurate that the tire track will normally vary less than one half a wheel width, forward or reverse.

To get more irrigated acres without buying more land or setting up a new water system, the Reinke Swing Arm Corner System is available on all new Reinke Irrigation Systems. In addition, it can be retrofitted on existing Reinke systems or many systems from other manufacturers.

If you would like more information about our products or services, please contact us today!

Reinke tower boxes provide a moisture-free environment for all electrical components. The double wall box design eliminates condensation and keeps electrical components cool. Reinke's injection molded design results in the strongest corrosion resistant tower box in the industry.

System alignment controls are centered over the hinge point of every span. This positioning provides precise alignment, even on irregular terrain.

Mechanical safety interlock prevents removal of cover during operation.

Retro tower box kits are available for ALL models of Reinke systems. They can also be modified to fit on competitive brand systems.

CENTER DRIVE

The Reinke Center Drive is engineered to give you years of trouble free service. Its high efficiency gear motor delivers exceptional torque to propel your system over the roughest terrain and worst soil conditions.

Only Reinke offers you a choice of three output RPM'S to match tire size and rotation time to your specific needs. Output RPM available: standard speed 36 RPM, high speed 73 RPM and low speed 24 RPM. A combination of these output RPM'S can be used to provide a smooth even water application to your crop.

HIGH EFFICIENCY HELICAL GEAR DESIGN ADVANTAGES:

SEVERAL TIRE SELECTIONS

Fine tuning your new Reinke system includes proper tire selection. This allows you to match span weight and tire sizes to soil and terrain conditions. Retro Drive Train Kits are available for all makes and models of center pivot systems.

If you would like more information about our products or services, please contact us today!

Harsh water conditions require corrosion resistant stainless steel pipe and an irrigation system that's built to last. To meet those conditions, we've added stainless steel to our line of waterline choices, which includes aluminum, chromium, nickel +, and galvanized steel. 0ur stainless steel systems (S-65G and S-85G) can be used to apply wastewater generated from livestock farms, municipalities, industrial operations, and more. Your local Reinke Dealer can help you determine whether stainless steel is right for your application needs.

The S-65G and S-85G both feature all stainless steel pipeline, flanges, and truss weldment brackets crafted from (all stainless steel material, supported by an all-galvanized steel undertruss.

When you're faced with harsh water conditions, the only choice is Reinke's S-85G and S-65G.

If you would like more information about our products or services, please contact us today!

Water conservation is a critical issue for you and your operation. Your Reinke Dealer is ready to assist you in selecting the right sprinkler package for maximum uniformity and efficiency.

meet your exact requirements, helping to increase yields and conserve water and energy. Reinke stocks a complete selection of the most efficient sprinkler packages available.

END GUNS

Reinke's overhang design allows for booster pump location near the end gun which eliminates friction loss cause by small diameter supply hoses required on last tower mounts. This design maximizes pressure and efficiency to the end gun.

Sprinkler conversion kits are available for EQUIP programs or just for upgrading any brand of center pivot.

SPRINKLER OPTIONS

Reinke's sprinkler options maximize uniform delivery to the root zone and minimize runoff. Whether choosing low, medium, or high pressure, sprays or impacts, Reinke offers a complete line of sprinklers to match your soil type and condition.

We also have booster pump retro kits to upgrade old center pivots and for EQUIP programs.

What is a thixotropic lubricant?

Sprinkler Lube 1200 is classified as a thixotropic lubricant. Thixotopy is a property that allows a substance to change from a thicker, gel-like state into a fluid where movement is present, yet return to the gel-like state when the movement stops. It remains thick where there is no movement.

What is it used for?

Sprinkler Lube 1200 is specially formulated for use in the gear boxes of center pivot irrigation systems. Its thixotropic properties allow it to have good flow back and heat transfer around bearings and gears, while remaining thicker at the outer areas of the gearbox to help with sealing - keeping water out and lubricant in.

What are some benefits of this product?

Sprinkler Lube 1200 assures maximum protection against corrosion of metal parts. This keeps the lubricant in good condition for extended service intervals. It is high-pass, which means it will not attack or corrode copper or brass, leaving the interior of the gearbox looking nearly new. The superior anti-wear extreme pressure agents of Sprinkler Lube 1200 protect against metal to metal contact and wear under excessive pressure or shock loads, increasing gear and bearing life. Special adhesive/cohesive additives make this product extremely sticky, which allows it to form a grease seal on worn shafts, keeping lubricant in and water out. This also keeps lubricant on metal parts eliminating dry starts or contact with moisture. Unlike traditional gear oil, the thicker, gel-like consistency of Sprinkler Lube 1200 makes it less likely to leak from the gearbox.

Sprinkler Lube 1200 is available in three different sizes for your convenience. Choose from the following: 35 lb. pail, 120 lb. Keg, 400 lb. Drum.

If you would like more information about our products or services, please contact us today!

1351 N 14 St Suite B

Oakes, ND 58474

View Location Map

Phone: (701) 742-2219

Fax: (701) 742-2631

Send Us An Email